Product Description

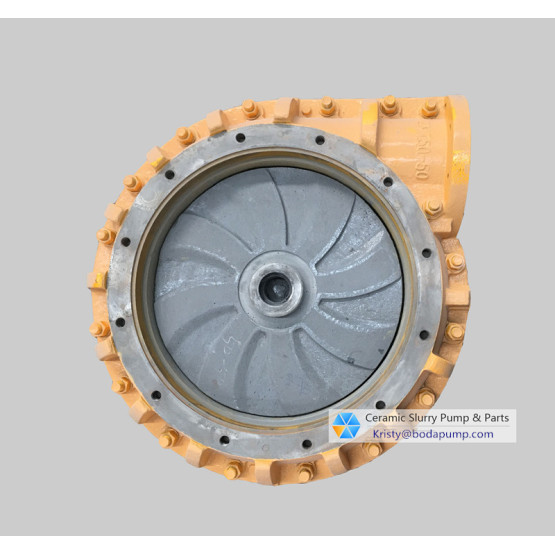

SiC Ceramic Heavy Duty Slurry Pump:

Considering important issues, including wear life, component arrangement, material composition and slurry abrasiveness, we developed SiC ceramic material for slurry pump. In regards of resistance, metals alloy have only corrosion and no abrasion, or have only abrasion and no corrosion in reverse. BODA ceramic meterial slurry pump covers both corrosion and abrasion perfectly.It has a longer service life but not such expansive as metal pump in total.

BODA ceramic slurry pump are widely used for convey media with large grain particles and the media is also corrosive. In fact, if you find that your slurry pumps are always broken after working for a short time, than you can chose our slurry pump. Begin with producing of silicon carbide (SiC) material and SiC-Si3N4 parts for many industries, BODA started to manufacture advanced slurry pump & parts at the beginning of Twentieth Centuery.

Ceramic Slurry Pump Features:

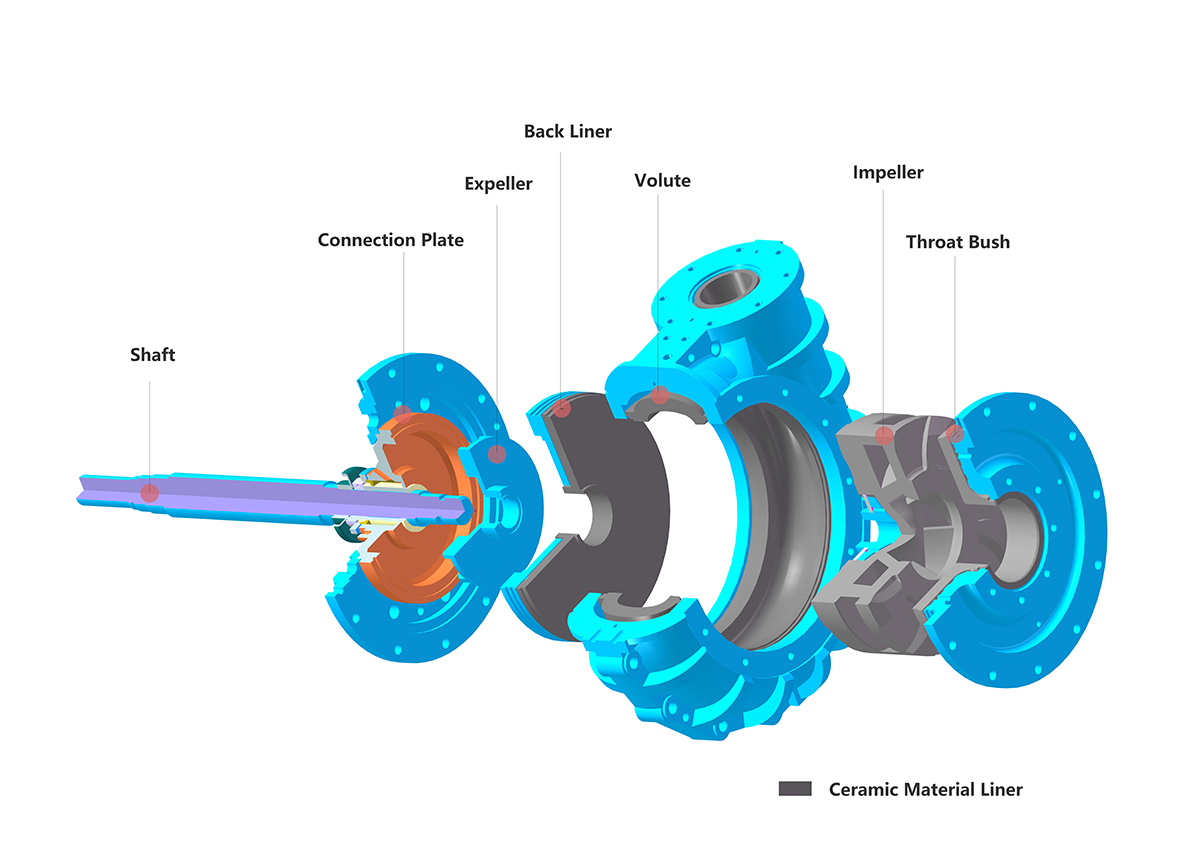

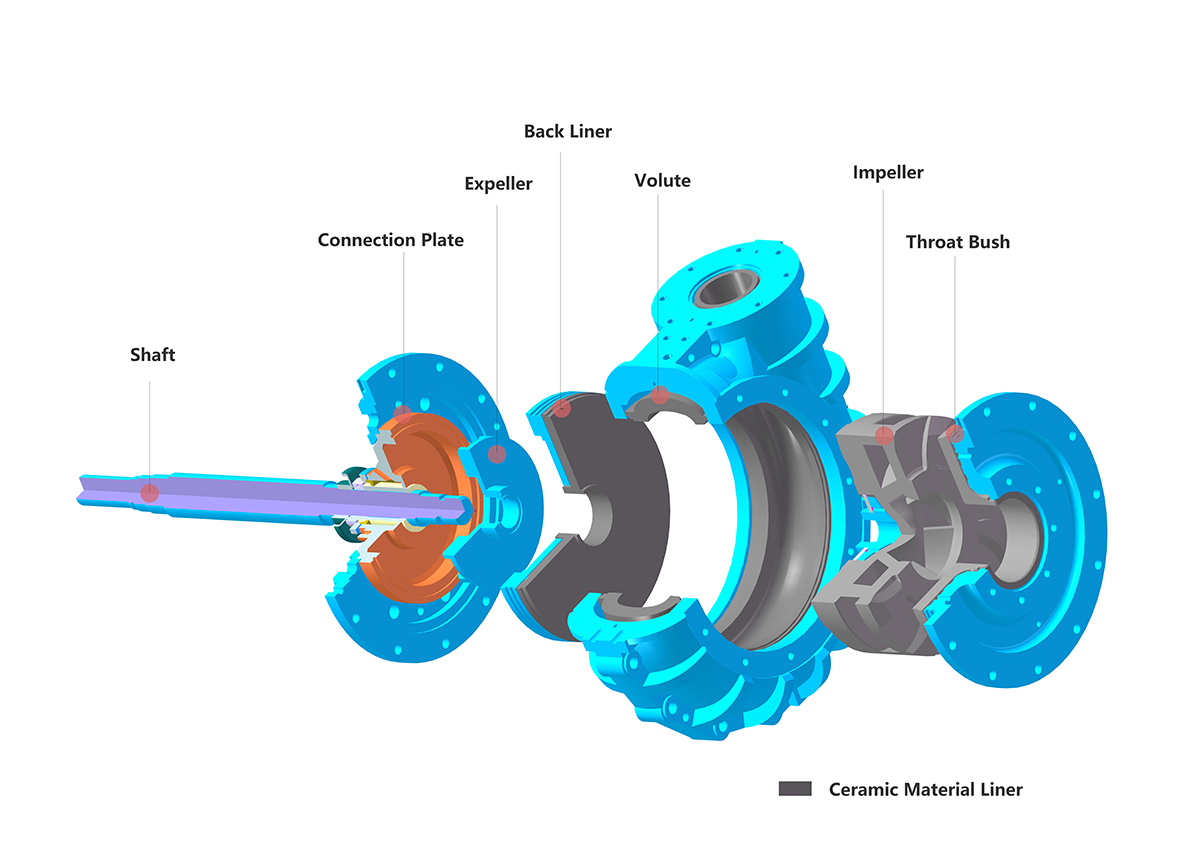

Thanks to the high temperature sintering process, we can munufacturing wet parts(impeller, throat bush, volute, back cover) by silicon carbide ceramic. These wet parts features many excellent performance as follows:

- Abrasion resistant

- Corrosion resistant

- Stand temperature up to 120 °C

- shockproof, anti impact

- compative price

Comparing with alloy slurry pump, the sic ceramic slurry pump, is always at a lower cost. Firstly, it gives the slurry pump a longer maintainance period. And sicilcon carbide is much cheaper than metal(A05, A49, Cr26, Duplex Stainless Steel-) .The SiC Ceramic slurry pump usually services for a time of 3-6 times longer than allloy slurry pump under same working condition.

.png) Contact Now

Contact Now