Product Description

Product Introduction

Application:

Series BHR slurry pumps are widely used in the mining, coal washery, power plant, metallurgy, petrochemical, building material, dredging and other industrial departments, etc. It is used in the various working sites including hydrocyclone feeding pump, underflow slurry pump (thickener underflow pump, filter separator underflow pump), flotation feeding pump, vibrating sieve feeding pump, shaking grading pressure pump, concentrate pump, and tailing pump.

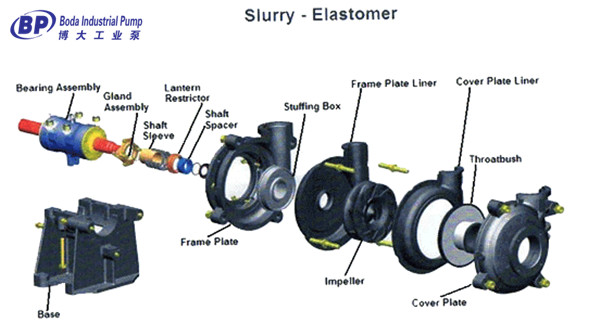

BHR series slurry pumps are similar to BH series in structure. The main difference between BH and BHR is the material of wet parts, which are natural rubber, chloroprene rubber or other wear-resistant rubbers. BHR are more suitable in delivering strong corrosive or abrasive slurries of small particle size without sharp edges.

Feature:

Outlet: 1-14 inch

Capacity: to 3060 m³/h

Head: to 63 m

Type: Centrifugal, Horizontal, Double Casing

Duty: Heavy duty slurry pump

Wet Parts Materials:Natural rubber

Replacement: Interchangeable with other pumps dimensionally

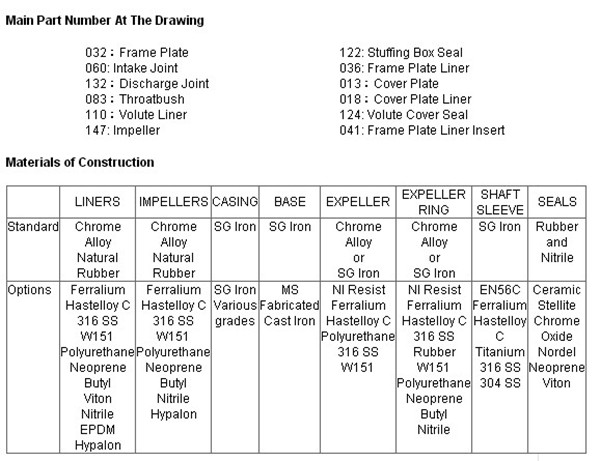

Material

The wet parts material for standard BHR series pump is natural rubber. With superb anti-corrosive performance, it is ideal for the delivery of strong corrosive or abrasive slurries without sharp edge.

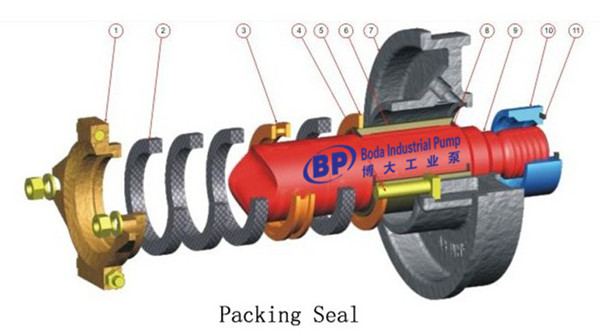

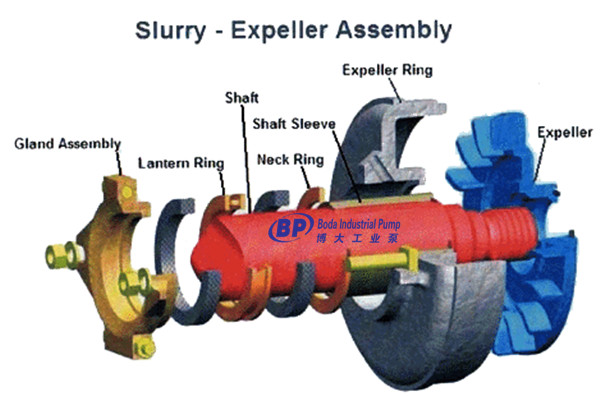

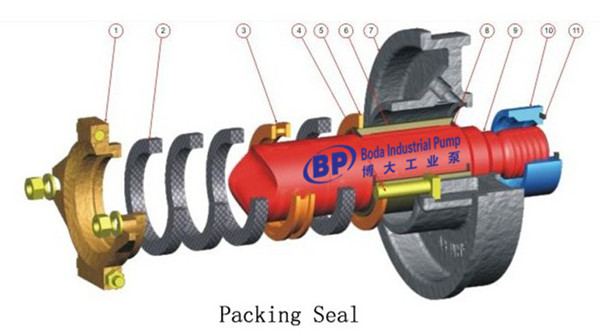

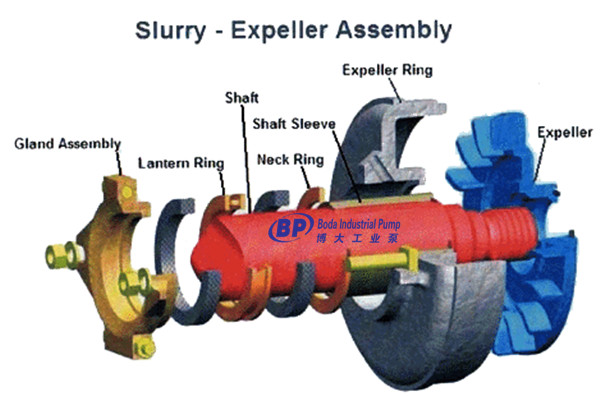

Shaft Seal

There are three standard shaft seal methods: Packing seal, Expeller seal, Mechanical seal.

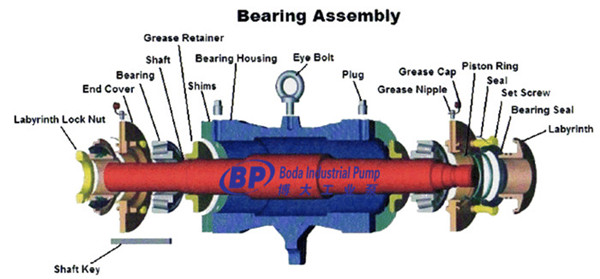

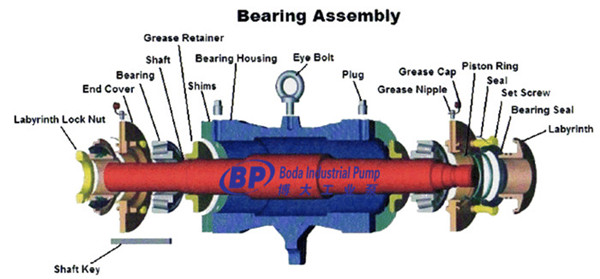

Bearing Assembly

Convenient to adjust the space between impeller and front liner and can be removed completely.

Slurry Pump Rubber Liners Sewage Pump Performance Table:

|

Pump Model

|

Allowable Max. Power(kw)

|

Clear Water Performance

|

|

|

capacity Q

|

Head H(m)

|

speed n(r/min)

|

Max.eff. η%

|

NPSH (m)

|

Impeller Dia(mm)

|

|

m3/h

|

l/s

|

|

1.5/1B-BHR

|

15

|

10.8-25.2

|

3-7

|

7-52

|

1400-3400

|

35

|

|

|

|

2/1.5B-BHR

|

15

|

25.2-54

|

7-15

|

5.5-41

|

1000-2600

|

50

|

2.5-5.5

|

178

|

|

3/2C-BHR

|

30

|

36-75.4

|

10-21

|

13-39

|

1300-2100

|

|

2-4

|

213

|

|

|

30

|

79.2-180

|

22-50

|

5-34.5

|

800-1800

|

59

|

3-5

|

245

|

|

4/3D-BHR

|

60

|

|

6/4D-BHR

|

60

|

144-324

|

40-90

|

12-45

|

800-1350

|

65

|

3-5

|

365

|

|

6/4E-BHR

|

120

|

|

8/6E-BHR

|

120

|

324-720

|

90-200

|

7-49

|

400-1000

|

65

|

5-10

|

510

|

|

8/6R-BHR

|

300

|

|

10/8ST-BHR

|

560

|

540-1188

|

150-330

|

12-50

|

400-750

|

75

|

4-12

|

|

|

12/10ST-BHR

|

560

|

720-1620

|

200-450

|

7-45

|

300-650

|

80

|

2.5-7.5

|

|

|

14/12ST-BHR

|

560

|

1152-2520

|

320-700

|

13-14

|

300-500

|

79

|

3-8

|

|

|

16/14TU-BHR

|

1200

|

1368-3060

|

380-850

|

11-63

|

250-550

|

79

|

4-10

|

1067

|

* Dimensionally Interchangeable with:

BHR ≈Warman®AHR

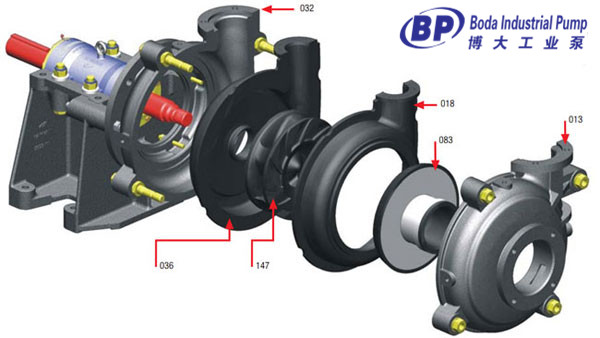

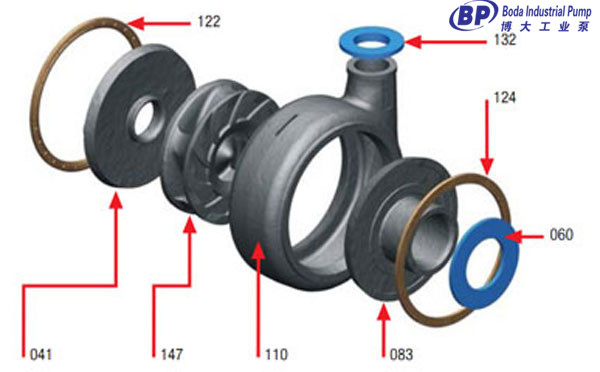

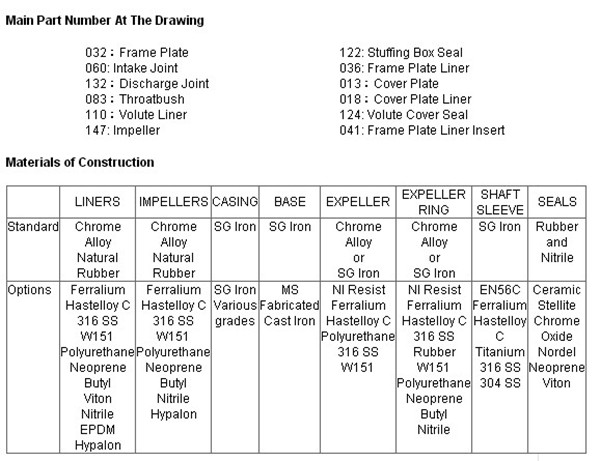

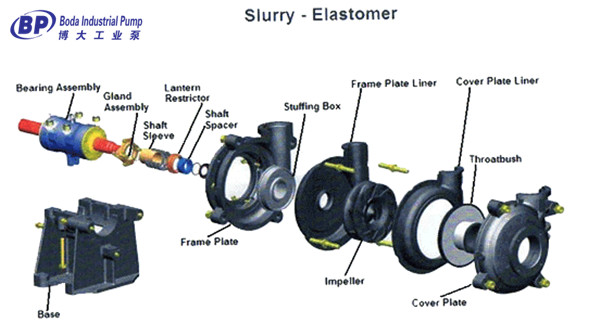

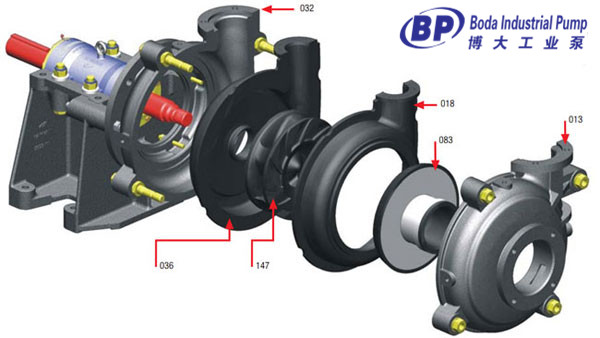

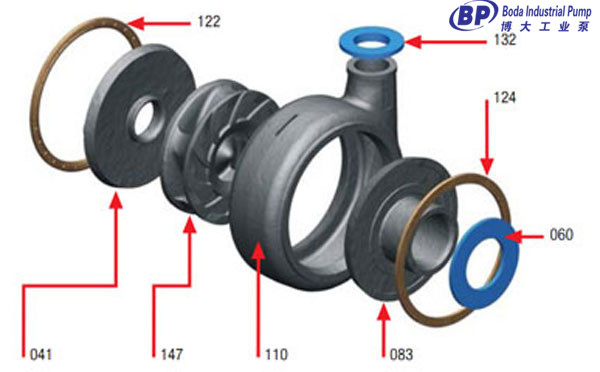

Rubber Lined Slurry Pump Structure:

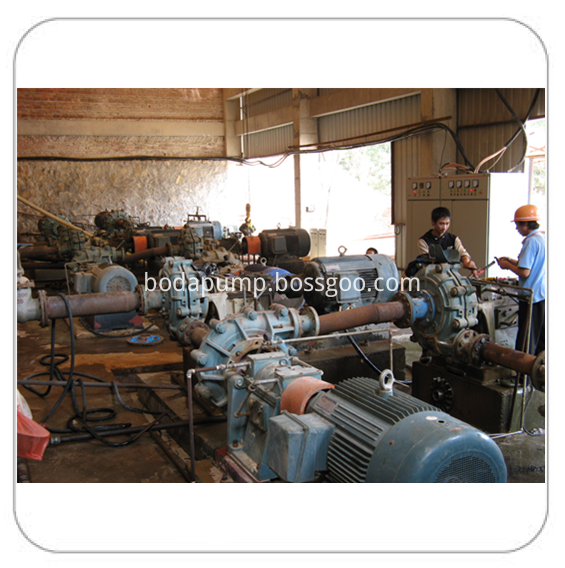

Slurry Pump Rubber Liners Sewage Pump Application:

.png) Contact Now

Contact Now