Product Description

FZB fluoroplastic self-priming pump overview

The FZB series of fluoroplastic self-priming pumps are designed and manufactured according to international standards and combined with non-metallic pumps. The pump body is made of metal shell with fluorine plastic. The over-flow parts are all made of fluoroplastic alloy. The pump cover and impeller are all sintered with metal inserts and fluoroplastic. The shaft seal is made of externally-type advanced bellows mechanical seal. The static ring is made of 99.9% alumina ceramic (or silicon nitride), and the moving ring is made of PTFE filling material, which has excellent corrosion resistance and wear resistance. The inlet and outlet of the pump are reinforced with cast steel to enhance the pressure resistance of the pump. The actual use shows that the self-priming pump has the advantages of corrosion resistance, wear resistance, high temperature resistance, no aging, high mechanical strength, stable operation, advanced and reasonable structure, strict and reliable sealing performance, convenient disassembly and maintenance, and long service life.

FZB fluoroplastic self-priming pump product features

The FZB series fluoroplastic self-priming pump features a self-priming function, which can pump liquid below the pump installation position, and has stable performance and simple operation. It only needs to be filled before the pump is used for the first time. And after use, there is no need to fill the liquid, it can be directly turned on. The self-priming height can be determined within 2 to 4 meters according to the density of the medium. It is a good choice for replacing the bulky submerged pump. The self-priming pump adopts the current advanced externally mounted PTFE corrugated pipe mechanical seal, which has multi-layer protection, which prolongs the service life of the machine seal. For conveying medium containing impurity particles, it can be equipped with a single-face hard and hard surface without cooling water ( Silicon carbide is mechanically sealed to silicon carbide, so the user should consider the solid content of the medium when selecting the type.

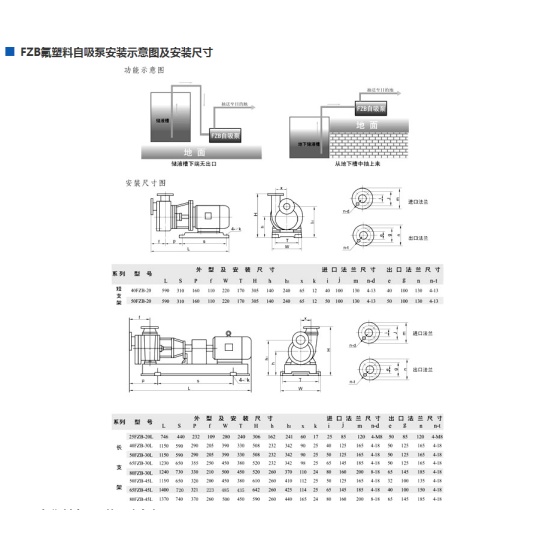

FZB fluoroplastic self-priming pump technical parameters

Flow rate: 1.5 to 60 m3/h;

Head: 15 ~ 50m;

Speed: 2900r/min;

Power: 1.5 ~ 15KW;

Import diameter: 25 ~ 80mm;

Applicable temperature: -20 ° C ~ 120 ° C.

FZB fluoroplastic self-priming pump main use

The FZB fluoroplastic self-priming pump is made of fluoroplastic and has self-priming function. Therefore, the FZB fluoroplastic self-priming pump is widely used, such as pumping corrosive liquid from the underground tank to the target location. The acid and alkali in the acid-base tank with no outlet at the bottom is pumped to the target site, or used for circulation between multiple acid tanks, or used for acid removal.

The user-friendly design principle and excellent working performance of FZB self-priming pump have become one of the most indispensable pump equipments for the use of units.

FZB fluoroplastic self-priming pump use precautions

1. The pump will arrive at the use site after long-distance transportation. Before installation, it is necessary to check whether the parts of the machine are intact. The fasteners should be tightened. Check the concentricity of the pump shaft and the motor shaft. If there is displacement, it should be corrected.

2. When installing, try to reduce the hydraulic loss of the suction pipe. Do not install elbows less than 90°. Do not use more than 2 elbows on the inlet pipe. The pump inlet should be equipped with a strainer to prevent large impurities from entering the pump. To ensure the normal operation of the pump, reduce the length of the inlet pipe as much as possible during installation (this will reduce the air in the inlet pipe, thus reducing the self-priming time and increasing the working efficiency).

3. The connecting bolts of the inlet pipe must be tightened evenly. The sealing must be tight. Never leak air. Use soft flange gaskets (such as fluororubber) as much as possible. Otherwise, the pump's self-priming performance will be seriously affected....

.png) Contact Now

Contact Now